Main features of the UMG 96RM-PN

MULTIFUNCTIONAL ENERGY ANALYZER WITH PROFINET

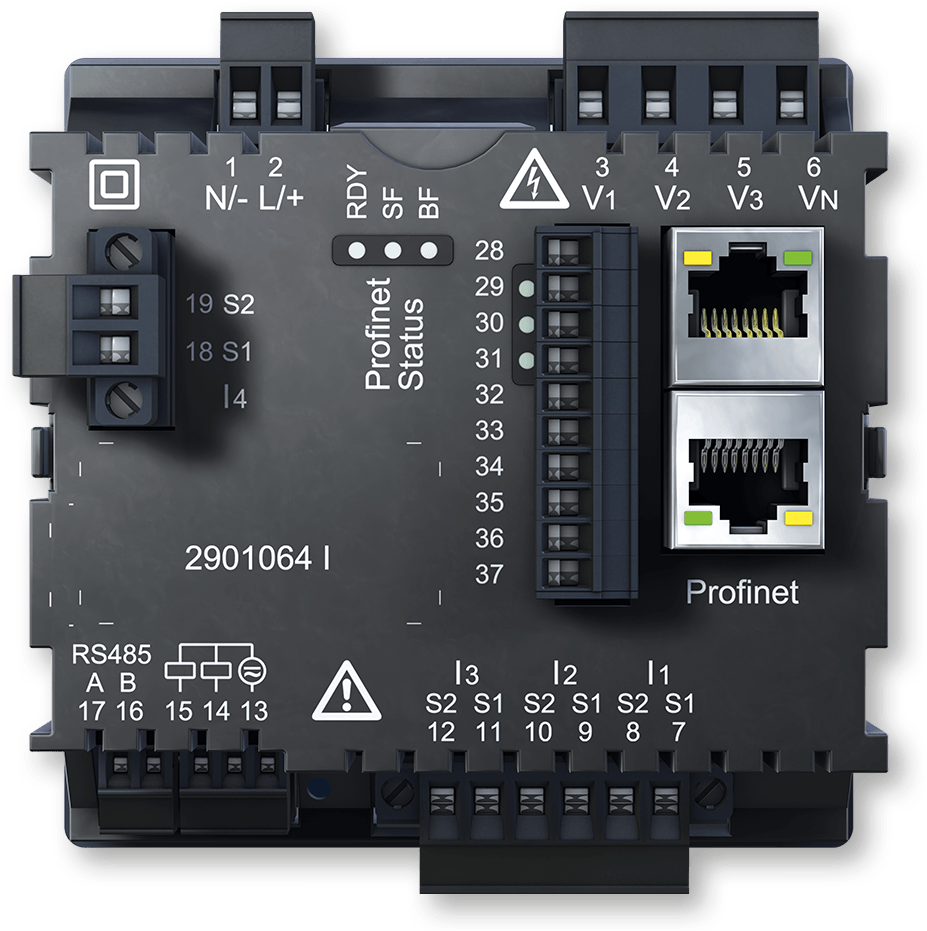

The UMG 96RM-PN power analyzer is used to determine the power quality and measures harmonics up to the 40th harmonic. It has two digital outputs and three further digital inputs and outputs, which can be specified as required. Two additional inputs are also included (analog, temperature or residual current input (RCM)).

ELECTRICITY CHANNELS

- Current measuring channel phase L1

- Current measuring channel phase L2

- Current measuring channel phase L3

- Neutral conductor current measurement channel (N measurement / overload)

- 2 x RCM (optional temperature input)

INTERFACES

- 2 PROFINET-compliant Ethernet interfaces and integrated switch for setting up line topologies

- Additional RS485 interface

- 2 digital outputs (pulse output, switching output, limit value output, logic output)

- Additional 3 digital inputs/outputs

RESIDUAL INTERFACES

- Software interface for querying measured values and configuration parameters via HTTP protocol, e.g. for integrating the measurement data into higher-level software solutions (BMS, PLC, SCADA, etc.)

- Machine-to-machine communication through simple architecture model

RCM (DIFFERENTIAL CURRENT)

- Fire and equipment protection

- Plant safety

- Compliance with regulations

- Identification of insulation faults

- Ensure system availability

WEBSERVER

- Real-time display of the current power/current and voltage values via the device homepage

- Device homepage can be called up at any time via the browser

- Display of the online measured values

GRIDVIS®-BASIC

- Visualization and evaluation of the measured values

- Simple creation of reports

- Development of energy management systems in accordance with ISO 50001

SIMPLE INTEGRATION OF THE MEASURING DEVICES INTO THE FIELDBUS LEVEL

Energy data collection has rapidly gained in importance in recent years. This relates less to the cost factor itself than to the realization that only fine-grained and high-resolution energy data acquisition can achieve the desired savings. For this purpose, the measurement technology must be integrated into existing systems – possibly even during operation.

PROFINET is ideal for this task, as this standard allows simple integration into existing fieldbus systems such as Profi bus DP, Profi bus PA, … This means that measurement devices such as the UMG 96RM-PN can also be easily integrated into the fieldbus level.

The simple installation reduces costs. This also enables migration from centralized to decentralized structures. There is no need for additional infrastructure components, as the UMG 96RM-PN already has a switch and two PROFINET interfaces on board, making it possible to set up line structures.

An energy management system can be easily implemented on the basis of this infrastructure. Via PROFINET, the recorded data can be sent to a central location in real time, stored centrally in powerful databases and made available for further processing in an architecture that is as open as possible.

Janitza has the right solutions for this – from stand-alone software to the cloud. This allows the user to implement their own, self-sufficient energy management or make use of Janitza’s service offerings.

COMMUNICATION FROM THE MACHINE TO THE WEB

Bringing Ethernet from the office to the plant field requires a number of enhancements, the most important of which is real-time capability. Depending on the application, a marketable Industrial Ethernet must be able to handle safety applications or the entire spectrum of drive technology, including clock-synchronous motion control with cycle times of less than one millisecond. This is achieved by a clever division of the protocols via the OSI layer model. Many solutions have been developed in this way. One of the most common is the open PROFINET standard, which also offers a high level of investment protection. Existing fieldbus systems such as Profibus DP, Profibus PA, AS-Interface and Interbus can be integrated without modifying the existing field devices.

RECORDING MEASUREMENT DATA WITH PROFINET

PROFINET already saves costs during installation, engineering and commissioning. Later on, the operator benefits from the easy expandability and high availability of autonomously operating subsystems. Accordingly, PROFINET is represented in all applications in mechanical and plant engineering: In the automotive industry, the paper industry, plastics processing, conveyor technology, the food industry and process engineering. It makes sense to also use this communication structure for machine-related energy data acquisition. For this purpose, Janitza has developed a PROFINET specialist based on the tried-and-tested UMG 96 devices: The UMG 96RM-PN – a measurement device that is far more than a standard version with a flange-mounted PROFINET interface.

UMG 96RM-PN, THE PROFINET SPECIALIST

The UMG 96RM-PN has two PROFINET IO-IRT-compliant Ethernet interfaces and an integrated switch. The structure of the fieldbus technology is presented in accordance with the standard using familiar line topologies. Parameterization and configuration can be carried out entirely via the Step 7® environment, for example. All measured values are mapped directly in the process data channel of the PLC. Its digital inputs and outputs can be used via both Modbus and PROFINET. Two analog inputs are available for 0-50 mA or temperature detection. A separate 5A current measurement channel can monitor the neutral conductor, for example.

All relevant measured variables and communication parameters can be displayed on the device’s own homepage. A REST interface enables measured values and configuration parameters to be queried via the HTTP interface. One highlight is the integrated residual current measurement (RCM), which can be used to detect incipient insulation faults at an early stage. This increases system availability and reduces the risk of fire.

LOCAL ENERGY SUPPLY IN TRANSITION

For some years now, the classic planning model and the technology of electrical energy supply have been changing due to many external circumstances. The requirements for more efficient grids play just as important a role as the constantly increasing feed-in power from renewable energies. Most of these influences affect the low-voltage grid. Critical operating states and overloads can occur there, as the classically planned grids were not designed for this.

Local network substations are increasingly becoming intelligent nodes: They take on tasks ranging from pure measurement, fault location, fault detection and power quality analysis to complete remote control or even automation. Especially when retrofitting existing local network stations, the following framework conditions must be taken into account.

SYSTEM SAFETY THROUGH RESIDUAL CURRENT MONITORING

The UMG 96RM-PN not only enables the continuous recording of consumption, but also residual current monitoring (RCM). RCM can be used to detect faults that a single system would only partially detect or not detect at all. This allows the user to react before fuses or residual current circuit breakers (RCD) switch off affected systems or socket circuits. This applies in particular to gradually increasing residual currents (e.g. triggered by insulation faults), excessively high operating currents or other overloads of system components or consumers.

But RCM can do even more – namely reduce the risk of fire! If the current flow is sufficiently high (with a full earth fault or correspondingly low-resistance connection), the upstream protective device will disconnect the electrical load from the mains. However, if the residual current is too low, the protective device will not trip. However, if the registered fault power exceeds a value of approx. 60 watts (approx. 261 mA at 230 V), there is still a risk of fire.

By parameterizing (i.e. defining the typical fault current in the “GOOD” state) the system in the new state and continuous monitoring, all changes in the system state can be identified from the time of commissioning. This can also be used to visualize creeping fault currents.

The RCM monitoring of the UMG 96RM-PN therefore not only increases system availability, but also reduces the risk of fire.

100% CONFORMITY WITH THE PROFINET STANDARD INCL. PROFIENERGY

The UMG 96RM-PN is PROFINET-certified and suitable for use with PROFIenergy. A PROFINET certificate certifies standard-compliant behavior in accordance with IEC 61158 within a PROFINET network and thus ensures a high quality standard.

PROFIenergy is a profile for energy management in production plants based on PROFINET. This allows energy consumption within the system to be controlled via open and standardized commands. With the use of PROFIenergy, external, hard-wired systems are no longer required.