BLK Maintenance & Service

Reliability needs maintenance! Each power factor correction must be examined as part of the periodic inspection. In the course of this inspection, the function and safety of the compensation system is checked.

With regular maintenance, impending damage is also detected early and repaired before a defect occurs. This maintains the operational reliability and usual high quality of your Janitza products.

Professional service

We carry out a professional service on your power factor correction systems, the results of which can also be used to detect damage or signs of ageing at an early stage. After an inspection, you also have the option of having your system properly repaired.

We carry out maintenance, inspections and repairs for power factor correction systems from all manufacturers.

Your advantage

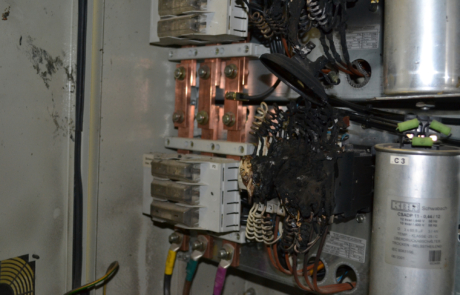

Power factor correction requires regular maintenance and testing to ensure the function and safety of the system. This enables defects to be detected and rectified in advance, thus preventing extensive damage such as fires, condenser explosions or even just the cost of reactive work.

If fires or other damage occurs due to unmaintained systems, your insurance company may insist on reimbursement of the costs incurred.

Possible damage

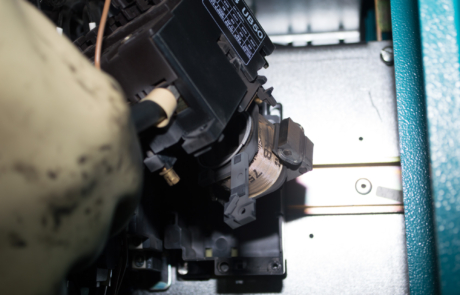

Unfortunately, damage to outdated, unmaintained power factor correction systems occurs time and again. Here are some examples: